Boiler Water Treatment Chemicals Calculations

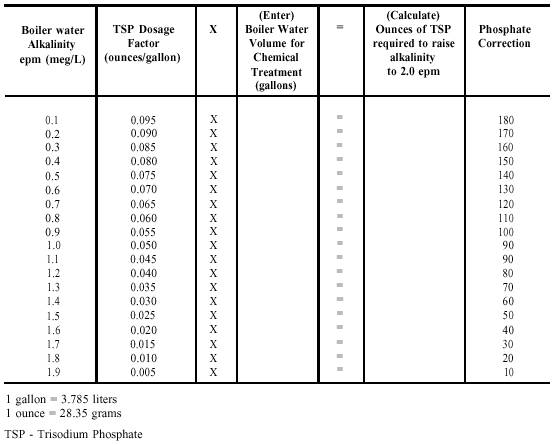

Arguably the most important function of a boiler water treatment program is scale control.

Boiler water treatment chemicals calculations. Part v internal treatment. Part iii water quality requirements and treatment programs. It precipitates hardness and provides necessary alkalinity and coagulants in one easy to use liquid product. A badly treated steam boiler is a potential bomb so getting the feed water quality and boiler water chemistry correct is.

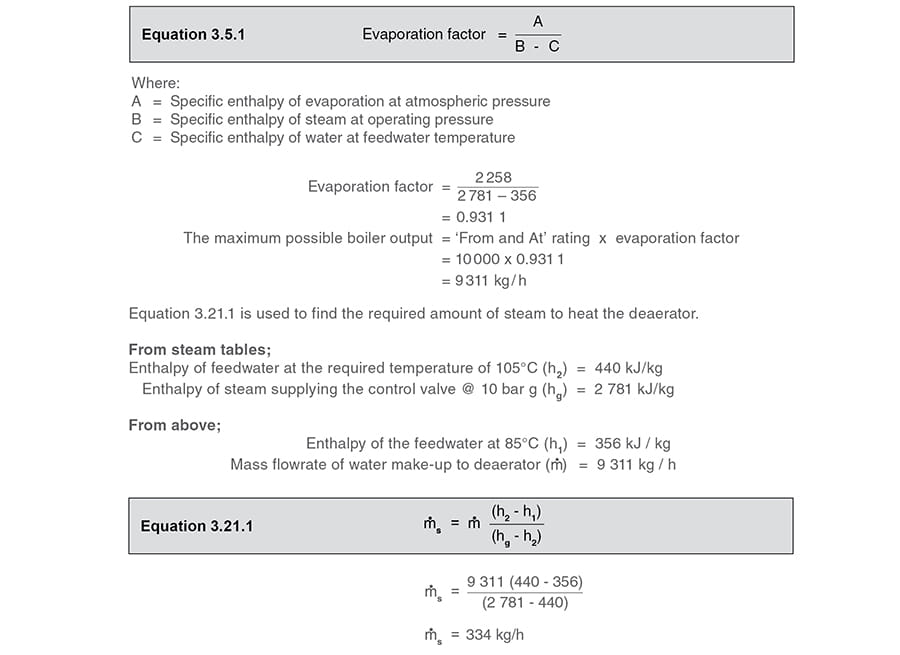

Part vi boiler water treatment important calculations. Lenntech can provide you all water treatment equipment including chemicals. Part viii chemicals handling solution preparation and. September 15 2006 chemicals used to treat steam boiler systems are applied based upon the demand and mode of reaction of each chemical used.

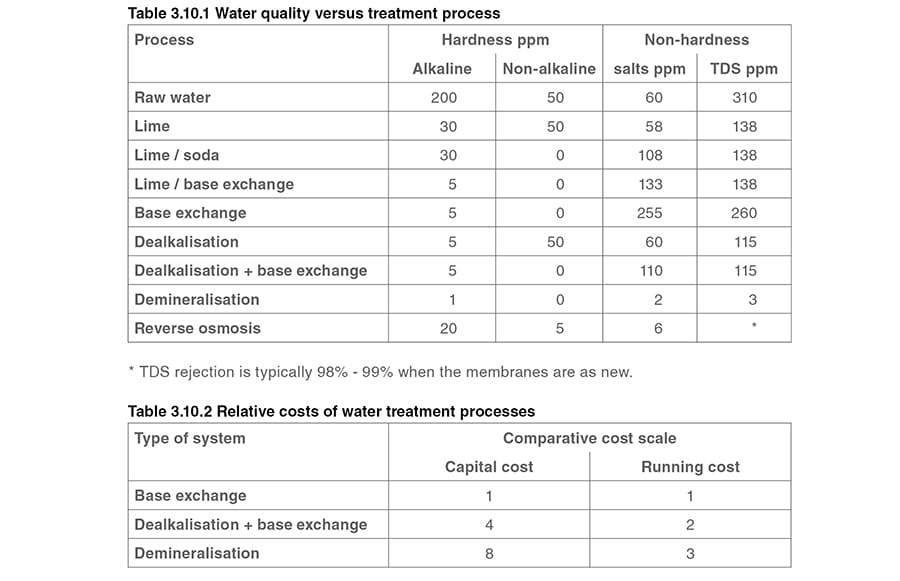

This book is divided into the nine parts. Assume boiler operates at 10 cycles of concentration and the residual boiler water alkalinity m is 250 ppm. Part ii boiler water troubles. A good boiler water treatment chemical program has the flexibility necessary to respond to these changes and provide complete scale and corrosion control under all operating conditions.

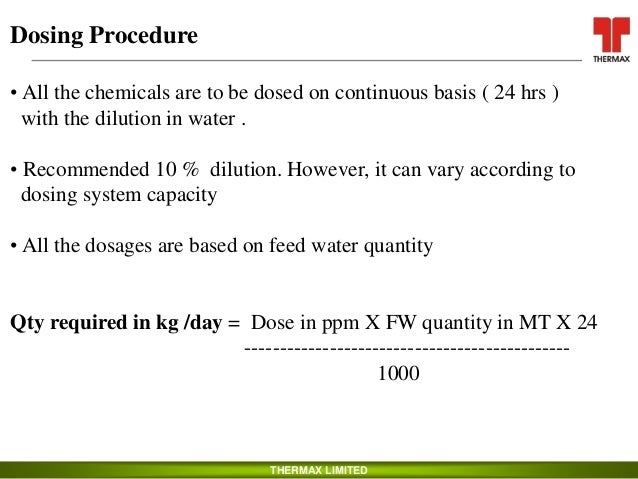

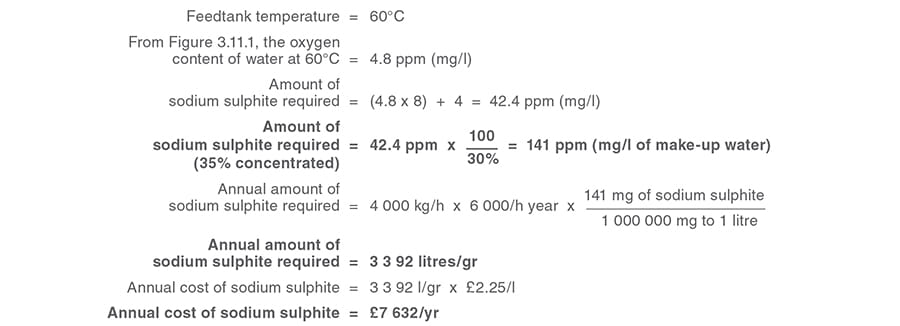

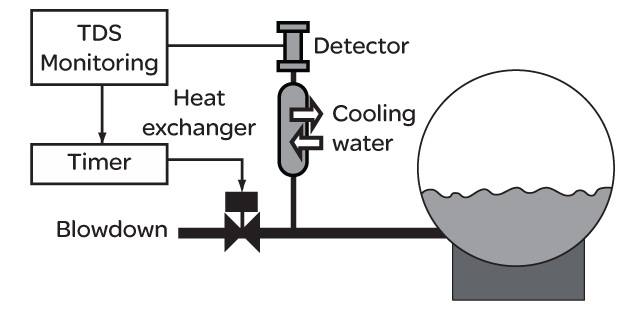

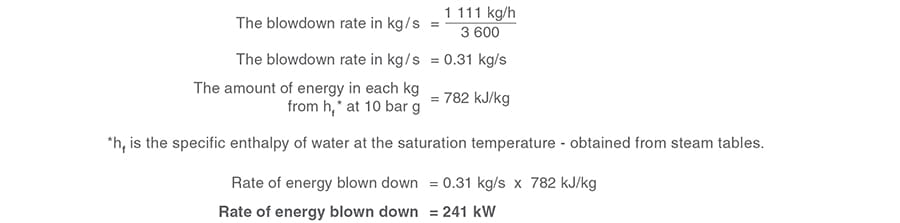

Boiler water treatment. The method for dosing the treatment chemicals will depend on the function of the chemicals the quality of the feed water and the individual boiler. Pumps used for dosing should be of sufficient capacity be able to supply against the line pressure. Boiler water treatment chemicals.

I have designed a formula with which to develop products for the treatment of boiler water vapor. Part iv external treatment. Our chemicals are suitable for land marine and heritage steam boilers. I am a professional in chemical industry with 20 years of industry experience developing complex chemical processes of organic chemistry.

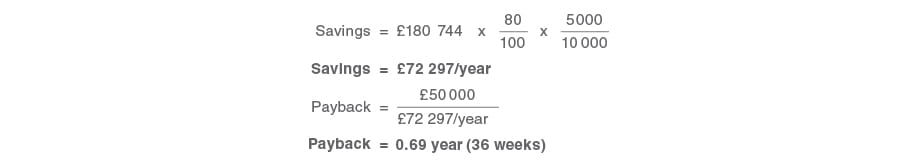

Chemicals will condition the water and protect boiler equipment heater pump. Part i boiler basics. Lenntech can advise you on treatments required on the make up water by providing calculations on mass balance in the steam boiler contributing for lower electricity consumption. Descaling inhibitors corrrocion and treatments for cooling towers.

Chemical treatment potentially filming amines molybdate or tannins oxygen is the corrosion inhibitor for quality stainless steel 316l low carbon so the construction of the first tank and related piping should be stainless steel. Part vii boiler startup cleaning layup and maintenance. As well as being a service company feedwater also manufactures and supplies a range of high quality boiler water treatment chemicals for uk and export customers.